The Measurement of Human Motion: A Comparison of Commercially Available Systems

Introduction

This experiment to compare the available motion analysis system was

conducted by Dr. James G. Richards, Ph.D. from the

University of Delaware, Newark DE. Dr. Richards was assigned the task to compare as

objectively as possible all the existing motion analysis systems and present it at the 3D Conference of Human Movement. The 3D conference is an

official function of the International Society of Biomechanics (ISB) and is considered to

be the most credible and influential in the field of Biomechanics.

The experiment was conducted and the results of this study were

presented with no interference from the companies whose products were tested. Dr. Richards

selected customers sites to conduct the experiment. In a few cases, such as with Elite and

CODA, results were returned to the companies' headquarters to determine the source for the

results which were accessibly inaccurate.

The results of this study were presented at the 3D Conference of

Human Movement at the University of Tennessee, Chattanooga, Tennessee. July 3rd, 1998.

The title of Dr. Richards' paper was: "The Measurement of Human

Motion: A Comparison of Commercially Available Systems." The

article published in the Proceedings were only some preliminary results and many of these

findings were incorrect. The correct, up-to-date results were presented during the

oral presentation and in the final paper by Dr. Richards.

The clarification of results between the preliminary, pre-Conference

publication and the appropriate, up-to-date results were particularly important for a

video based system such as the APAS system. For the APAS system, the initial results

were based on data obtained from only 2 cameras which was inappropriate for an experiment

utilizing the experimental test device. The test device had a mechanical arm which

rotated 360 degrees and, therefore, obviously required a minimum of 5 cameras in order to

see each marker from at least two cameras views. Restricting the data collection to only

two cameras created some peculiar situations such that nearly 176 degrees of motion were

detected by one only camera, 112 degrees by two cameras, and the remaining degrees

were undetected by any camera. Because of the specific conditions inherent with this test

device, the experiment had to be repeated utilizing 5 cameras. All other venders used 6

cameras. The final paper that was presented, included 5 cameras which is the only

way to be able to analyze this particular device. All the other companies used 6 cameras

and even using 6 cameras, two of the companies could not produce reliable and valid

results. However, with normal, straightforward experimental testing of human

movement, three cameras and, frequently only two cameras, are adequate with the APAS

system.

The slides utilized here were taken with digital camera during

Dr. Richards' presentation. Therefore, the quality of the slides were affected

by the angle from where the pictures were shot during the presentation. In

no way has Dr. Richards supported, condoned, or contributed to this article on our web

site. Since the presentation was delivered publicly in an international conference,

the material was deemed to be in the public domain and we are pleased to have the

opportunity to present these results here.

Procedures

"The purpose of this study was to critically review and

analyze the available commercial systems in light of their ability to generate basic

coordinate data, and to provide information regarding the advantages or disadvantages of

their unique characteristics."

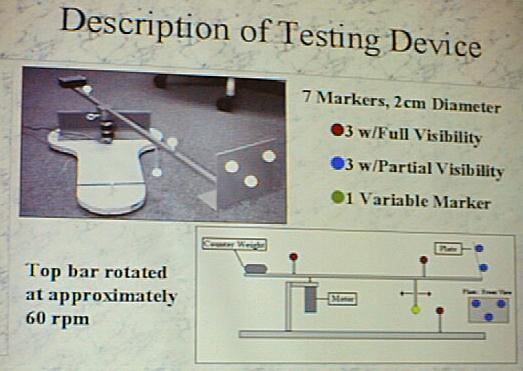

This first slide illustrates the testing device.

(As noted previously, these slides were presented by Dr. Richards and were

photographed from the audience. Dr. Richards' presented his findings and has not

contributed to this web site article.)

Slide 1. Description of the testing device. (Slide was photographed

during the original presentation at the 3D Conference of Human Movement, Chattanooga

Tennessee, July 3, 1998)

The tests utilized a device that systematically moved markers within the

measurement system's calibrated space in order to acquire approximate measures of system

accuracy and efficiency. This setup required a minimum of 5 cameras situated at

particular angles in order to see each marker with at least 2 cameras. However, in some

cases, the resultant video provided views which, for a few frames, some markers could be

seen from only one camera. Although the other systems utilized six cameras, the APAS

system utilized only five cameras. In spite of this difference, the APAS was able to

interpolate the points and yielded excellent results.

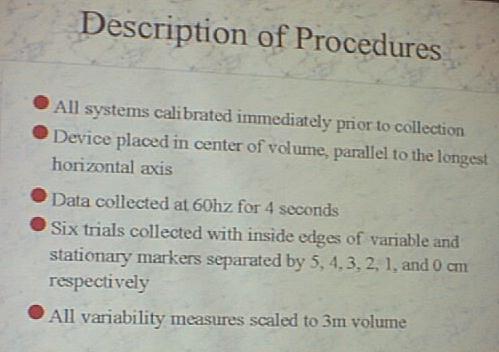

Slide 2 illustrates an original presentation slide which described

the testing procedures.

Slide 2. Description of Procedures. (Slide was photographed in the original presentation)

The systems that were reviewed included the:

- Ariel system

- Motion Analysis HiRes system

- Peak Performance's Motus system

- Qualisys ProReflex system

- Vicon's 370 system

The Ariel System used 5 Cameras while all others used 6 cameras.

The Elite and CODA Systems were unable to produce reliable results, in most

cases, and, therefore, were not included in this report.

Analysis of Results

The testing device, which can be seen in

other pictures, supported seven markers. Two markers were place 50 cm apart on top

of a rigid aluminum bar that rotated in the horizontal plane at a rate of approximately 60

rpm. Three markers were placed in a triangular pattern on a plate mounted vertically

at the end of the bar. The plate was perpendicular to the bar and the markers were

placed on the outside surface so that they were only visible to the subset of cameras as

the bar rotated. A sixth marker was mounted to the base of the device on a 3-cm

rigid post. The final marker was mounted to a post on the bottom of the rotating

bar. The post placed this marker at the same height as the stationary base-mounted

marker. The position of the marker below the bar was adjustable along the length of the

bar so that the minimum distance between the stationary marker and the orbiting adjustable

marker could be controlled.

Deviations from known distances between fixed markers and deviations

from known angles were determined for each of the systems measured.

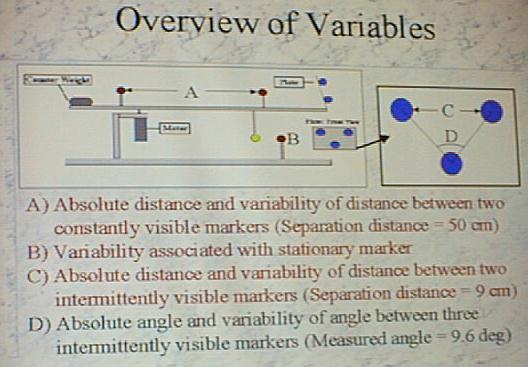

Slide 3 illustrates the original slide from

the presentation at the 3D conference, describing the various variables utilized in the

study.

Slide 3. Overview of Variables (Slide was photographed in the original presentation)

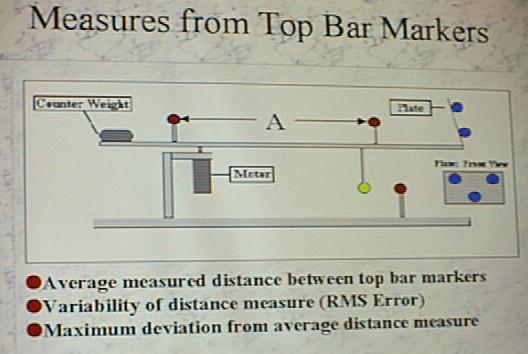

Specific measures derived from the seven markers were as follows:

1. The measured distance between the two markers on the top of the

rigid bar was calculated for each frame of the trials. Measured distances were

averaged within each trial and subtracted from the known distance of 50.00 cm to produce

an average absolute error associated with each of the systems. Noise associated with

this measure was determined by taking the RMS of the difference between the average

measured distance and the measured distance in each frame of the data. Slide 4 was

photographed in the original presentation and illustrates these measurement parameters.

Slide 4.. Measures from Top Bar Markers (Slide was photographed in the original

presentation)

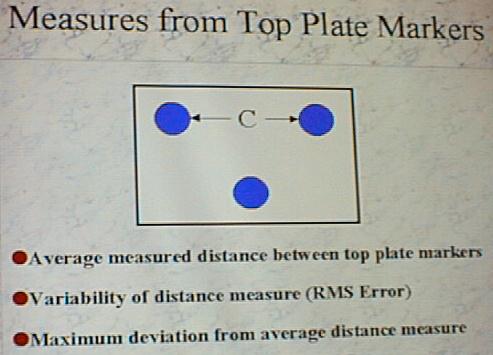

2. The measured distance between the two markers on the top to the plate was

calculated for each frame of the trials and compared to the known distance of 9.00 cm to

produce an average absolute error associated with each of the systems. The maximum

absolute error associated with the distance calculation in each trial was also recorded.

Noise associated with this measure for each trial was determined by calculating the

RMS. Slide 5 was taken at the original presentation and illustrates these

measurements.

Slide 5. Measures from Top Plate Markers (Slide was photographed in the original

presentation)

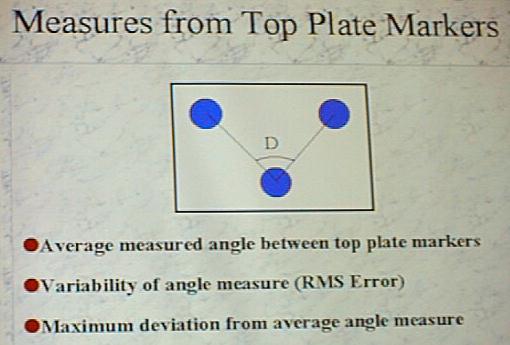

3. The three markers on the plate were used to define an angle with the bottom

plate marker serving as the vertex of the angle. The angle formed by the three markers on

the plate was calculated for each frame of the trials. Measured angles were averaged

within each trial and subtracted from the known angle of 95.80 degrees to produce an

average absolute error associated with each of the systems. In addition, the maximum

absolute error associated with the angle calculation in each trial was recorded.

Variability associated with this measure for each trial was determined by taking the RMS

of the difference between the average measured angle and the measured angle in each frame

of the data. Slide 6 was photographed at the original presentation and shows the angle.

Slide 6. Measures from Top Plate Markers. (Slide was photographed in the original

presentation)

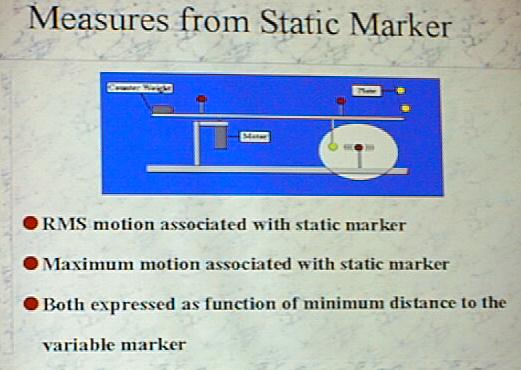

4. The variability associated with the stationary marker measurement was

determined by calculating the RMS of the difference between the average stationary

position and the measured stationary marker position in each frame of the data. Slide 7

illustrates the original slide photographed at the presentation and shows the measures

from the static marker.

Slide 7. Measures from Static Marker. (Slide was photographed in the original

presentation)

Visitor Number

Since 7-8-98

[Go to Home Page]

[Top] [Next Page -

Ranking]